The function of air shower

Air showers are an important part of cleanroom facilities, used to remove surface particles from personnel and goods entering or leaving the controlled environment. They work by forcing high-velocity air through nozzles, which dislodges and removes loose particles from the person or object Air showers are essential in ensuring that controlled environments remain uncontaminated and meet industry standards.

1. What are Air Showers?

Air showers are specialized, self-contained structures that use high-velocity air jets to remove loose particles from surfaces, clothes, and equipment. They are usually installed in cleanroom facilities and used to reduce the amount of contamination that can be brought into the environment by personnel and goods. Air showers work by creating a high-velocity air stream, which is directed at the person or object entering the facility.

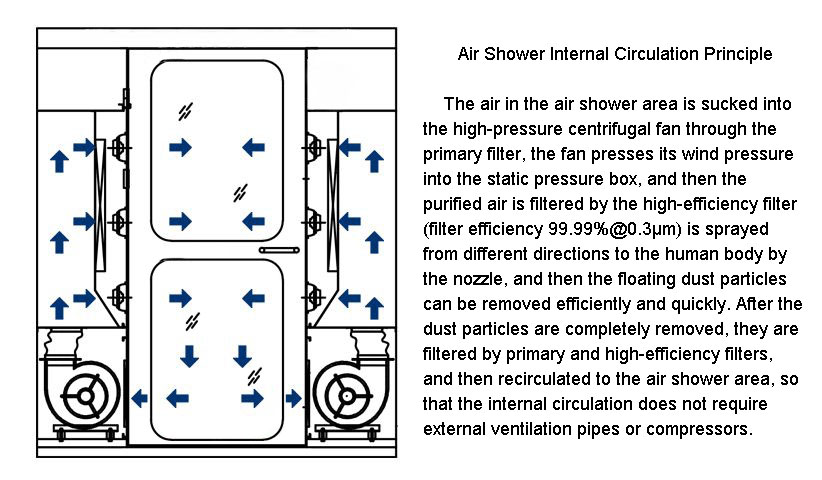

2. How do Air Showers Work?

Air showers work by forcing high-velocity air through nozzles, which creates a turbulent environment that dislodges and removes particles from surfaces, clothes, and equipment. The air is then filtered before being recirculated back into the cleanroom facility. The nozzles are strategically placed to ensure that all surfaces of the person or object are exposed to the high-velocity air stream.

3. Benefits of LIPU Air Showers

① Reduction of Contamination

One of the main benefits of air showers is their ability to reduce the amount of contamination that can be brought into a controlled environment. By removing loose particles from personnel and goods before they enter the facility, air showers minimize the risk of contamination and ensure that the cleanroom environment remains uncontaminated.

② Protection of Personnel and Environment

Air showers also protect personnel working in the cleanroom facility from exposure to contaminants that may be brought in from outside. This is particularly important in industries such as pharmaceuticals and electronics, where exposure to even small amounts of contaminants can have severe consequences. Additionally, air showers help to protect the environment by preventing contamination of the cleanroom facility and the products being manufactured.

③ Energy Efficiency

Air showers are designed to be energy-efficient, with low power consumption and minimal noise levels. They are typically equipped with a variable speed motor, which allows for the adjustment of the air flow rate depending on the specific needs of the facility.

④ Cost Savings

Air showers are a crucial component in cleanroom facilities as they help to minimize the amount of contamination that enters the controlled environment. By reducing contamination, air showers can help to minimize the risk of product recalls, which can be both costly and time-consuming. In addition to reducing the risk of recalls, air showers can also help to extend the lifespan of expensive equipment by minimizing the amount of contamination that comes into contact with it. This, in turn, can reduce the need for costly repairs and replacements, making air showers a wise investment for any cleanroom facility.

⑤ Compliance with Industry Standards

Air showers are designed to meet the strict requirements of various industry standards, such as ISO. Compliance with these standards is crucial in ensuring that the products being manufactured are of high quality and meet regulatory requirements.

EN

EN

EN

EN ES

ES TH

TH VN

VN